Despite infrastructure hurdles, companies in Africa are taking the innovation route to reduce losses in the food value chain. Cold chain facilities play a prominent role in these efforts.

An estimated 1 in every 4 people in sub-Saharan Africa is malnourished. Yet, a third of the food produced for human consumption every year gets lost or wasted, and forty percent of these losses happen at post-harvest and processing levels in Africa. The losses can be traced back to challenges with harvesting techniques, and storage and cooling facilities.

According to the Food and Agricultural Organisation of the United Nations (FAO), “the lack of reliable and adequate cold chain facilities in sub-Saharan Africa is one of the main causes of losses of perishable products, which are estimated to be about 25-30 percent for animal products and 40-50 percent for roots, tubers, fruits and vegetables.”

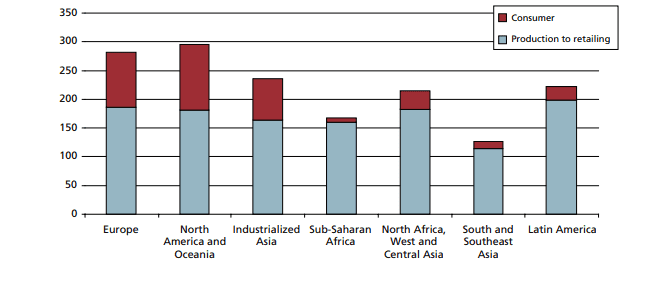

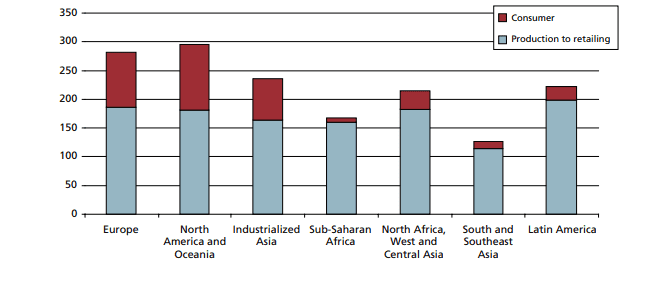

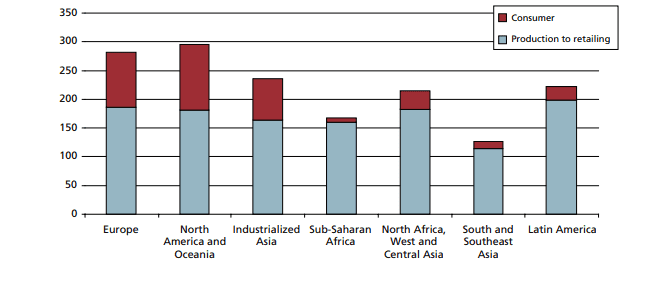

Per capita food losses and waste (kg/year)

Source: FAO

Cold chain solutions provide a temperature controlled supply chain, thereby preserving food during the time between harvest and consumption. FAO identified access to energy, shortage of qualified staff and spare parts, poor logistics, weak organisation and implementation of controls for compliance with standards, and relatively low traded volumes as challenges for the development of cold chain technology on the continent.

However, there are significant cold chain solutions in Africa already. About 10,000 rural farmers in Kenya cool and ripen bananas and other farm produce with InspiraFarms-developed cold storage units at a Twiga Foods warehouse in Nairobi. The units use 70 percent less energy than traditional refrigeration systems and have up to two days of thermal backup capacity if there’s a power outage.

In Rwanda, with support from the World Bank, the government installed 10 InspiraFarms solar-powered cooling units in rural areas that have no electricity or refrigeration. The units are expected to serve about 100,000 smallholder farmers.

Efforts to use cold chain solutions in Nigeria, to address food insecurity issues, have also been made. APM Terminals, an international container terminal operating company, organised a trial shipment of 18 tonnes of fresh tomatoes from Kaduna to Lagos, a 621-mile trip. The tomatoes were delivered, however, the company did not make additional shipments, citing poorly established retail networks and road congestion as challenges.

ColdHubs, a company founded by Nnaemeka Ikegwuonu, a Nigerian entrepreneur, develops solar-powered refrigeration units. Each ColdHub can fit approximately three tonnes of perishable food, and ColdHubs operates a simple pay-as-you-store model, with farmers and retailers paying less than US$0.50 to store one crate for one day. ColdHubs had five units in Nigeria by October 2018 operating at full capacity, with plans to set up at least twenty more in 2019, and expand to other African countries.

Oghenetega Iortim, the CEO of Gricd Frij, a cold chain solution in Nigeria developed to prevent post-harvest losses in agriculture and provide storage and transportation of medical supplies, says his team is working on scaling their current solution–luggage-sized cold chain boxes for transporting medical supplies–into larger, more economical models for farmers.

Oghenetega mentions that transporting vaccines also has an effect on food losses, as animal vaccines are sometimes affected by breaks in the cold chain. “There are a lot of disease outbreaks that occur in cattle and poultry in Nigeria, for which vaccines exist. However, these diseases still occur in vaccinated animals because some of the vaccines have lost their potency as a result of breaks in temperature control during transportation.”

There are alternatives to cold chain that others are exploring too.

Coating+, a company formed by a group of biochemistry students at the University of Ilorin, Nigeria, employed biotechnology to create a transparent gelatinous coating that is sprayed onto fresh fruit and vegetables to prolong their shelf life. It’s made using a combination of chitosan, a sugar extracted from shrimp shells, along with soy protein and micronutrients. Coating+ won a US$10,000 prize in 2018, with plans to conclude regulatory approval and increase production capabilities.

The Rockefeller Foundation also launched YieldWise in 2016, a US $130 million initiative to demonstrate how the world can halve food loss by 2030. They are currently focused on four value chains in three countries: maize in Tanzania, cassava and tomatoes in Nigeria, and mangoes in Kenya. The initiative is investing in technology innovations like mobile processing and solar-drying to extend the shelf life of the crops. Thus far, YieldWise boasts 20-30 percent loss reduction as “early results” of their efforts.

Progress is being made to eliminate waste, with the creative entrepreneurs and active investments in the space, but more still needs to be done.

The post Curbing Losses in the Food Value Chain in Africa appeared first on TechCabal.